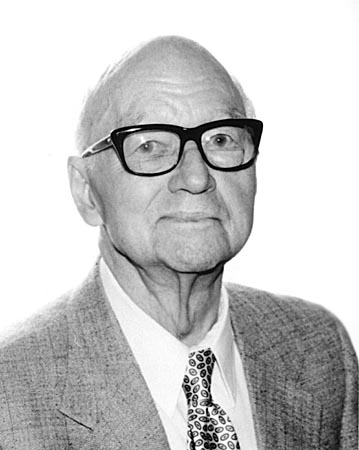

rnst Mahler was born in Vienna, Austria, in 1887. In 1912, he graduated with distinction from Technische Hochschule (Technical University) Darmstadt, Darmstadt, Germany, where he studied industrial chemistry, having specialized in cellulose chemistry and the scientific study of papermaking.

Mr. Mahler joined Kimberly-Clark Corporation in Neenah, Wisconsin, in 1914 as a paper chemist. He established the first research and development department at Kimberly-Clark and one of the first in the industry. Mr. Mahler helped to accelerate the company’s use of chemical controls in papermaking and led the firm in the development of many of today’s standard paper and pulp products.

The first creped wadding in the United States was developed by Kimberly-Clark, with Mr. Mahler providing the knowledge and experience. The commercialization of his creped wadding technology led to the establishment of a multibillion dollar industry in the United States and around the world. This fluffy wadding product was first used as a substitute for cotton in surgical dressings during World War I. From this, Kimberly-Clark created dozens of creped wadding products, including such trademark names as Kotex and Kleenex.

Mr. Mahler led Kimberly-Clark in the development of the first refiner groundwood pulp and its use in making bookpaper. For many years after 1915, practically all rotogravure in the country was on groundwood bookpaper from Kimberly-Clark mills.

He authorized the first high-speed experimental forming unit to further research on tissue and papermaking, which led to the development of the crescent former tissue-making process.

In 1929, Mr. Mahler was one of the original founders of the world-famous Institute of Paper Chemistry, an affiliate of Lawrence College. The institute became a major contributor to the technological depth and breadth supporting the paper industry. Further, it has been a source of highly-trained scientific and managerial professions for the paper industry. Mr. Mahler served the institute as its first president and as board chairman. Later he was made honorary chairman.

Mr. Mahler also helped found the Technical Association of the Pulp and Paper Industry (TAPPI) and was the recipient in 1932 of the gold medal award for contributions to the industry. His part in founding the institute and TAPPI were cited by Brown University when it awarded him an honorary doctor of science degree in 1937.

During World War 1I, he was a member of the purchase policy division of the Army Service Forces and helped formulate policies, review legislation, and implement utilization of small war plants. For nearly five months in 1945, he was in Europe as an expert consultant in charge of paper production and organization rehabilitation of the paper industry in Belgium, Holland, France, and Germany. Mr. Mahler also served as a member of the United States Reparations Commission in Russia, Berlin, and Potsdam. In 1946, he was awarded a certificate of appreciation from the War Department and the Presidential Medal of Freedom.

Mr. Mahler retired in 1952. During his 38-year career with Kimberly-Clark, he served the company as a chemist; technical director; general superintendent; vice president of operations; and executive vice president. He held professional memberships in TAPPI; National Association of Manufacturers; American Pulp and Paper Industry; and The Institute of Paper Chemistry.

In addition, he was a trustee of Lawrence College and a director for Allis Chalmers Manufacturing Company; Neenah First National Bank; Milwaukee First Wisconsin National Bank; First Wisconsin Trust Company; Wisconsin Bankshare Corporation; president of the Neenah Municipal Museum Foundation; and vice president of the American Horse Show Association United States Olympic Equestrian Team.

In 1954, Lawrence College awarded him an honorary doctor of law degree, and in 1958, Technical University Darmstadt awarded him an honorary doctor of engineering degree.

Mr. Mahler died in 1967 at the age of 79. He and his wife had two children, Ernst Jr. and Mrs. Richard (Polly) Stafford.