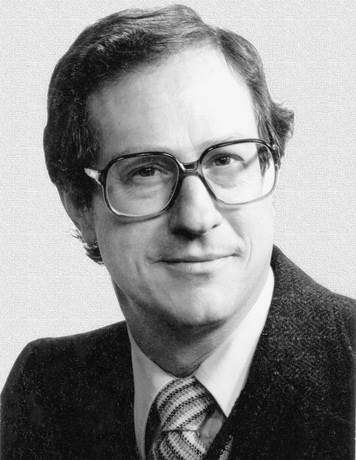

Theodore “Ted” Clifford Kennedy was born the son of an iron worker in McKeesport, Pennsylvania on May 26, 1930. He studied at Duke University, graduating Phi Beta Kappa with a degree in civil engineering in 1952. After graduation, he worked for twenty years at Rust International where he rose to the position of company president in Montreal, Canada.

In 1972, Kennedy, along with two of his fellow workers, Peter Bolvig and Bill Edmonds, left Rust and formed BE&K, Inc. In the beginning, BE&K concentrated on providing engineering and construction services to the pulp and paper industry. In 1975, their leadership in the pulp and paper industry was cemented after the successful installation of a newsprint machine for Southland Paper in Lufkin, Texas. Not only did the company successfully install the machine, but they also completed installation well over a month before the deadline, proving their team was both efficient and competent. The company evolved into design and construction of new plants and expansions, building the first recycled newsprint mill and introducing the first tube conveyor for wood yards.

Kennedy was instrumental in developing component staging for the erection of recovery boilers and the use of laser technology for complex paper machine rebuilds. This technology won the prestigious NOVA award from the Construction Innovation Forum.

BE&K continued to grow, serving the forest products industry and expanding into the communications industry and the energy sector worldwide. In 1992, out of concern for the wellbeing of his employees, Kennedy began offering guaranteed annual wages to ease workers in on-again, off-again construction schedules. BE&K also began offering childcare at on-site facilities.

Kennedy became President and CEO of the company in 1983, and served as Chairman and CEO from 1989 until 1995, and as Chairman from 1995 until 2003. He holds the title of Founder, BE&K, Inc.

Kennedy is a member of the National Academy of Engineering and the National Academy of Construction. He served as National President of Associated Builders and Contractors in 1980, was Chairman of the Construction Industry Institute in 1988, and served fourteen years on the Construction Advisory Committee for The Business Roundtable. He is a member of TAPPI and was elected a TAPPI Fellow in 1993. Engineering News-Record magazine recognized Mr. Kennedy as a “Man Who Made His Mark” in 1981 and 1989. In 1999, the magazine named Kennedy as “one of the top 125 industry leaders within the past 125 years.” In 1981, Duke University honored Kennedy’s professional distinctions with the Distinguished Alumnus Award.

Theodore Kennedy has six children, Ted Kennedy, Jr., Page Kennedy Barker, Carolyn Kennedy Munn, Julia Kennedy Fletcher, Ann-Keith Kennedy, and Cameron Vaughn Kennedy; and three grandchildren. (Mr. Kennedy died in 2012)